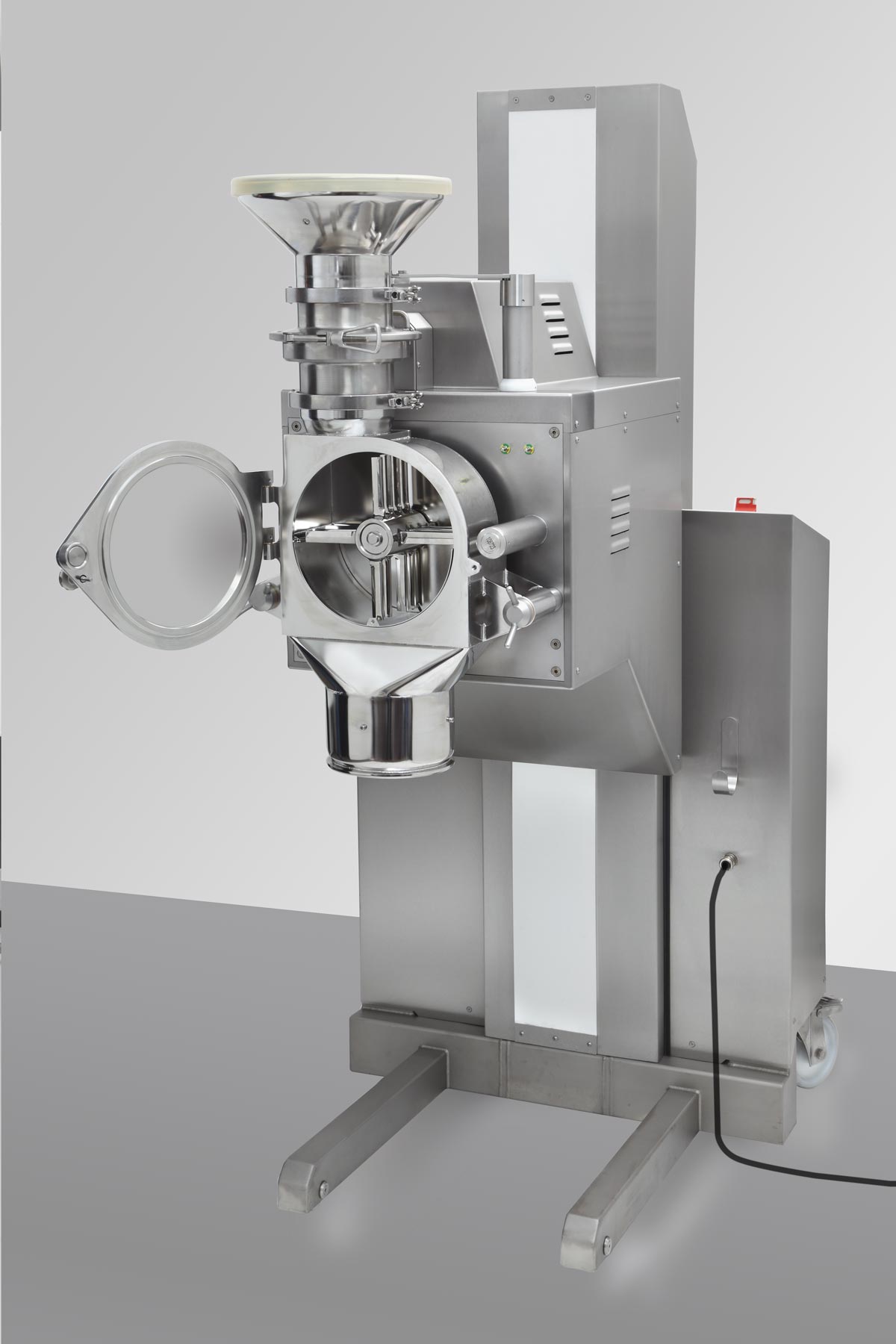

The Bohle Turbo Mill BTM 150 is a hammer mill that increases the viability of challenging wet or dry pharmaceutical and nutraceutical ingredients. It employs a dual-sided blade assembly that has a hammer-like side to shatter dry materials and a knife-like side to slice wet materials. Users simply flip the rotor based on their ingredients. Operating at high-speeds of 1,000 to 6,000 rpm, the mill reduces material size to 0.2-3 mm at outputs of 1,500 kg/hr. This mill is suitable for continuous or batch production, research and product development.

Best Milling Results

Material is evenly filled into a milling chamber via an automatic rotating valve that protects against overfilling. The BTM 150 discharges finished particles through a screen that regulates final particle dimension based on 0.2-3 mm screen selection. The blade and screen perform in conjunction to determine final product size. The mill rotor can be reversed to deal with specific product behavior while rotation direction remains unchanged.

Fast Dismatling for Cleaning Cycles

The BTM 150 offers easy transport on a mobile carriage. An integrated lifting column enables variable height adjustment to fit into almost any pharmaceutical production line. The mill is cGMP-compliant and is manufactured with 316 stainless steel for parts that contact ingredients. The mill can be dismantled for cleaning in less than three minutes.

The benefits of the Bohle Turbo Mill 150:

- Particle size < 100 μmScreen sizes from 0.3 to 3 mm

- Speed of 600 – 6,000 rpm

- Rotor with hammer and knife sides

- Automatic rotary valve protects against overfilling

- Easy to operate, modular and compact

- Integrated mobile lifting column

- Gasket made of PTFE or silicone – cGMP, FDA compliant